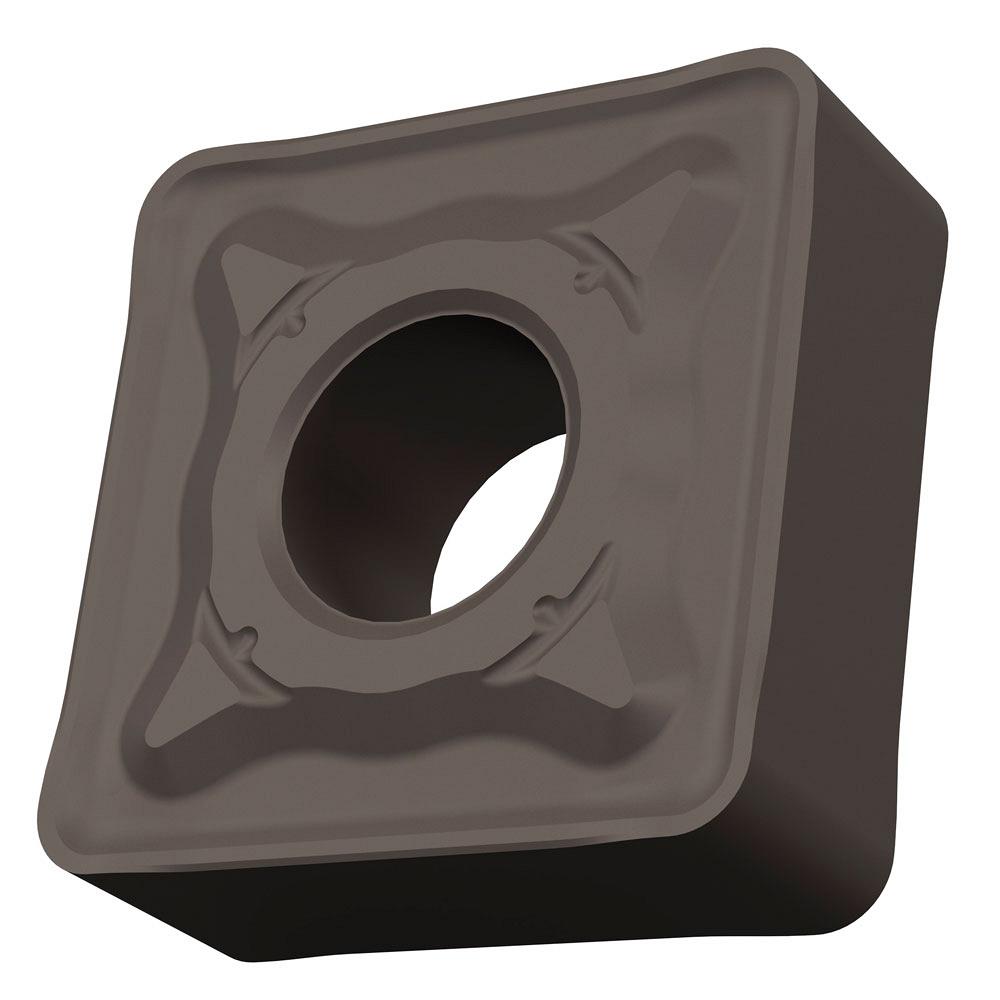

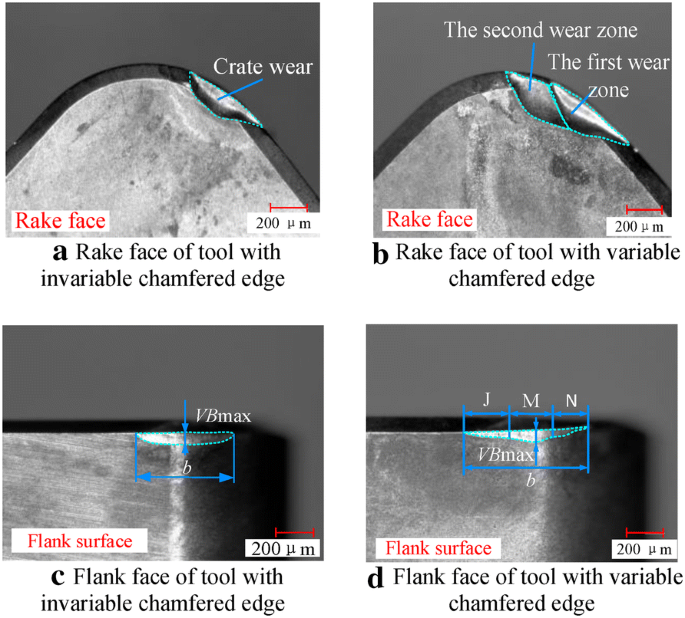

Experimental Study on Wear Characteristics of PCBN Tool with Variable Chamfered Edge | Chinese Journal of Mechanical Engineering | Full Text

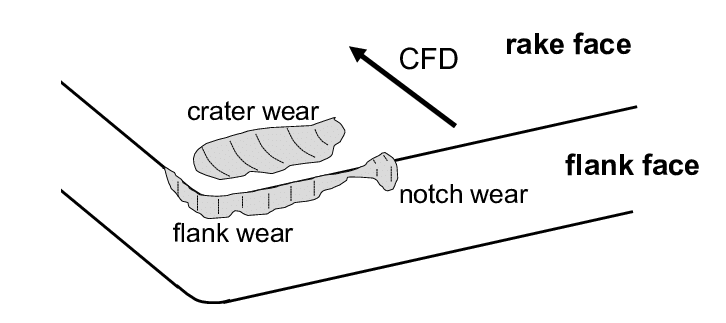

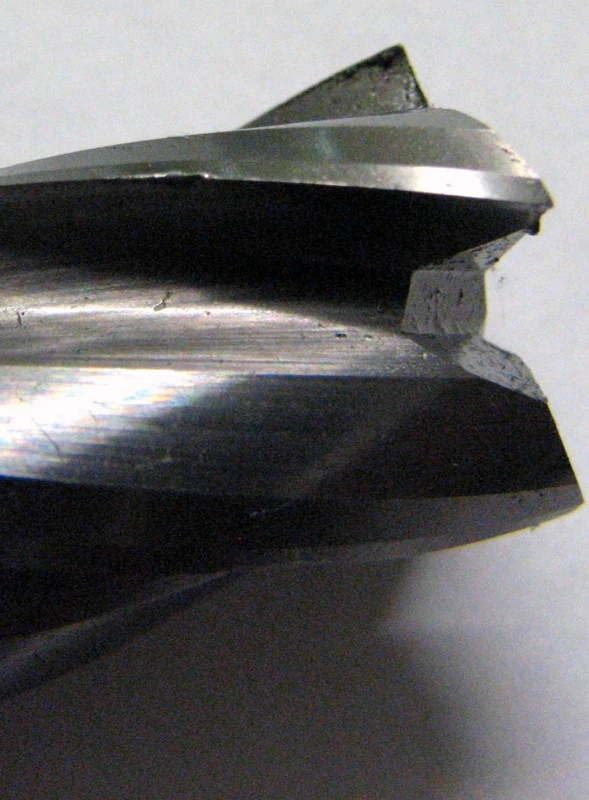

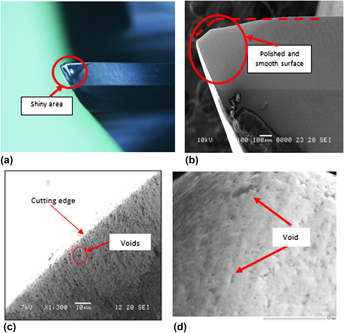

Study on wear mechanism of solid carbide cutting tool in milling CFRP | Journal of Materials Research | Cambridge Core

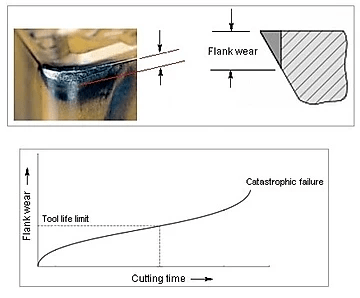

Experimental Investigation on Tool Wear in AISI H13 Die Steel Turning Using RSM and ANN Methods | SpringerLink

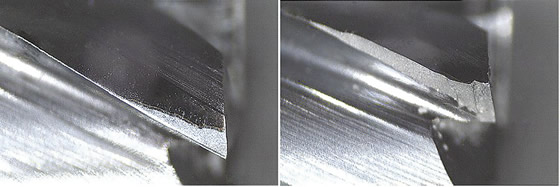

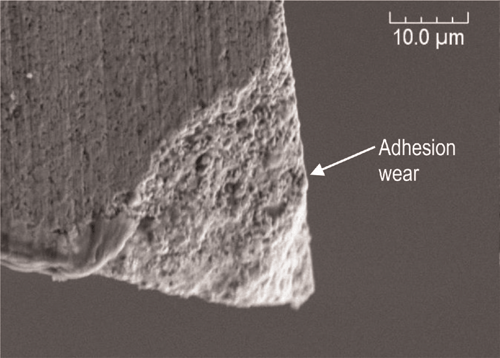

![PDF] Wear mechanisms of cutting tools in high-speed cutting processes | Semantic Scholar PDF] Wear mechanisms of cutting tools in high-speed cutting processes | Semantic Scholar](https://d3i71xaburhd42.cloudfront.net/583d65b08be770f5d8c698e2d32542524add2dd4/7-Figure8-1.png)